- Chemical Auxiliary Agent[9]

- Concrete Admixtures & Mortar Admixtures[9]

- Other Construction & Real Estate[2]

- Other Plastic Building Materials[1]

- Refractory[10]

- Ceramics[6]

- Other Dinnerware[1]

- Other Filter Supplies[3]

- Other Inorganic Salts[2]

- Feed Additives[2]

- Other Non-Metallic Minerals & Products[1]

- Water Treatment[6]

- Chloride[1]

- Bricks[2]

- Chlorate[1]

- Chemical Reagents[1]

- Waste Management[1]

- Other Chemicals[1]

- Cement[1]

- Other Tools[1]

- Contact Person : Mr. Zhang Zhiyong

- Company Name : Yixing Runlong Trade Co., Ltd.

- Tel : 86-0510-80383589

- Fax : 86-0510-80381638

- Address : Jiangsu,Yixing,No 23-331,Chemical Market

- Country/Region : China

- Zip : 214200

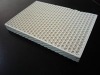

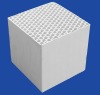

alumina ceramic

Honeycomb ceramics

Honeycomb ceramic regenerator is a regenerative high-temperature combustion technology (HTAC technology) the key and core components. Regenerative high temperature combustion technology (HTAC technology) is a new concept of combustion technology, which the flue gas waste heat recovery and efficient combustion and reduce NOx emissions from organically integrate technologies to achieve energy efficiency and limit the limit to reduce NOx emissions from volume of a dual purpose. Honeycomb ceramic regenerator has been widely used in metallurgical machinery industry a variety of Pusher-type furnace, reheating furnace, heat treatment furnace, forging furnace, melting furnace, ladle / tundish toasters, soaking furnace, radiant tube burners, hood-type furnace, blast furnace hot blast stove; building materials industry, a variety of ceramic kilns, all kinds of glass furnace; petrochemical industry, a variety of tube-type furnace, cracking furnace and other industrial furnaces.

Specifications

Specifications | 1 | 2 | 3 | 4 | 5 | 6 | |

L×W×H/mm | 150×150×300 | 150×150×300 | 150×150×300 | 100×100×100 | 150×100×100 | 100×100×40 | |

Holes | 25×25 | 40×40 | 50×50 | 3128 | 36×24 | 48 | |

Hole grid width /mm | 4.9 | 3.0 | 2.26 | 2.65(3.0) | 3.1 | 1.57 | |

Thickness /mm | 1.0 | 0.7 | 0.7/0.55 | 0.55(0.55) | 1.0 | 0.5 | |

Surface /m2/m3 | 540 | 825 | 1005 | 1065(990) | 760 | 1510 | |

Open Ratio /% | 67 | 65 | 57/64 | 67(91) | 55 | 57 | |

Physical properties

Performance | Aluminum Porcelain | Mullite | Dense Cordierite | cordierite Porous | Stoneware | Corundum | Mullite - cordierite |

Density | 2.7 | 2.9 | 2.4 | 1.9 | 2.3 | 3.2 | 2.9 |

thermal expansivity /201000/106·-4 | 57 | 5.56.5 | 2.53.5 | 1.252.5 | 57 | 67 | ≤5 |

Heat capacity /201000/J/Kgk | 11001300 | 11001300 | 8001200 | 750900 | 800900 | 13001400 | 11001300 |

Heat shock /k | min200 | min230 | min250 | min360 | min150 | min260 | min300 |

maximum operation temperature /k | 1400 | 1600 | 1300 | 1300 | 1150 | 1750 | 1550 |

Chemical properties

Performance | Aluminum Porcelain | Mullite | Dense Cordierite | Porous cordierite | Stoneware | Corundum | Mullite - cordierite |

SiO2 | 4045 | 2530 | 4552 | 4652 | 6875 | 811 | 2836 |

AL2O3 | 4855 | 6672 | 3236 | 3237 | 2026 | 8592 | 5565 |

MgO | - | - | 58 | 1216 | 0.150.25 | 1.82.5 | 2.53.2 |

Fe2O3 | ≤1.0 | ≤1.0 | ≤1.0 | ≤1.0 | ≤1.2 | ≤0.5 | ≤0.8 |

Na2O+K2O+CaO | 4.05.5 | ≤1.0 | ≤1.0 | ≤1.0 | 2.54.0 | 0.51.2 | ≤1.0 |

TiO2+BaO | - | - | ≤0.5 | ≤1.0 | ≤0.5 | - | - |

alumina ceramic